The 2025 National Science Popularization Month event in Jinchang kicked off at Jinchang People's Cultural Plaza on Sept 5.

Jinchuan Group's renovation project transforms Anji Primary School in Jishishan county, Linxia Hui autonomous prefecture in Northwest China's Gansu province.

The high-performance atomized nickel powder produced by the powder material plant of Jinchuan Group Nickel and Cobalt Co Ltd has strong market competitiveness.

Guangxi Jinchuan Xinrui Gas Co Ltd recently celebrated a milestone as its first batch of high-purity liquid argon passed customs inspection and was successfully shipped to Vietnam.

Jinchuan Group supplies all cables for the Phase I project of the Astana Light Rail Transit system in Kazakhstan.

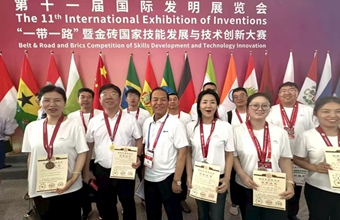

Jinchuan Group received 10 awards at the 11th International Exhibition of Inventions in Guangzhou, Guangdong province from Aug 22 to 24.

An unveiling ceremony for the LME-approved HK delivery warehouse takes place on Aug 19 in Hong Kong, China.

Dubbed Jinchang city's "new landmark" by locals, Jinchuan Group's two talent apartment buildings have not only become a highlight of the city, but also a testament to the group's commitment to the philosophy that "talent is the foremost resource".