Jinchuan Nickel-Cobalt Research and Design Institute at the Western China International Fair for Investment and Trade

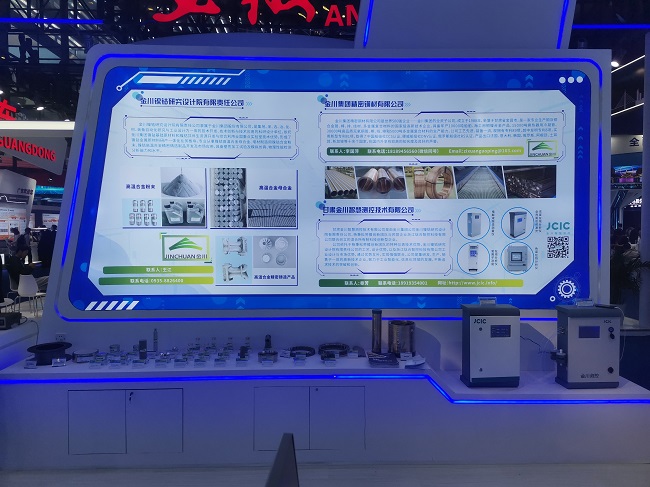

Jinchuan Group's Nickel-Cobalt Research and Design Institute showcased its cutting-edge material research and development capabilities at prestigious events, like the 5th Western China International Fair for Investment and Trade, the 23rd China International Fair for Investment and Trade, the 2023 World Manufacturing Convention, the 25th China International High Tech Achievement Fair, and the 135th China Import and Export Fair.

Leveraging the technological and equipment advantages of Jinchuan Group's State Key Laboratory for the Development and Comprehensive Utilization of Nickel, Cobalt and Associated Resources, the institute has established an integrated nickel-cobalt metal new material research and production business. Supported by a team of highly skilled R&D personnel and a professional operations team, the institute focuses innovating nickel-cobalt superalloys, nickel-cobalt alloy powders for additive manufacturing, and precision casting products. The institute boasts advanced capabilities in plastic processing testing, simulation, and physical property analysis.

Key products and innovations:

1. Superalloy Master Alloys

The institute has developed a complete suite of superalloy master alloy products, supported by advanced facilities such as 50kg, 200kg, and 500kg vacuum melting furnaces. These capabilities enable customized research, development, and production of superalloy master alloys, including cast, corrosion-resistant, and powder superalloys, as well as medical alloys. Key products include series like K418, K4169, K452, and K4648, offered in bar and ingot specifications (Φ80, Φ50, Φ30mm), with customization available. These products are widely applied in aviation engines, gas turbines, automotive superchargers, and medical instruments.

2. Superalloy Powders

The institute utilizes state-of-the-art ultra-high-speed plasma rotating electrode equipment and German aerosol equipment to produce high-quality superalloy powders. These powders, including brands such as GH4169, GH3536, GH3625, and CoCrMoW, are available in various particle size specifications (e.g., 15-45μm, 15-53μm, 45-105μm, 50-150μm) and can be tailored to customer requirements. Applications span aerospace, medical, and petrochemical industries, where stable and superior performance is critical.

3. Precision Casting Products

Expanding Jinchuan's nickel-cobalt industrial chain, the institute develops superalloy precision casting products for aviation engines, gas turbines, and large turbochargers. With proprietary precision casting technology, the institute manufactures components such as supercharger turbines, aircraft engine turbine discs, guide vanes, gas turbine blades, and smoke turbine blades. These products serve critical roles in aerospace, marine power generation, petrochemical equipment, and more.

Jinchuan Nickel-Cobalt Research and Design Institute at the China Import and Export Fair

Jinchuan Nickel-Cobalt Research and Design Institute at the China Hi-Tech Fair