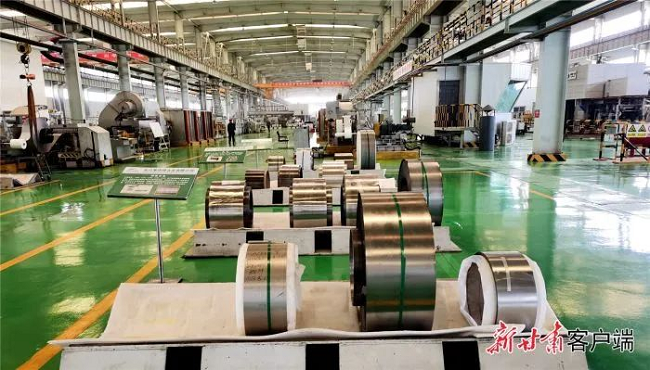

The production workshop of the hand-tearable nickel strip [Photo provided to en.jnmc.com]

Industrial transformation and green development

Though having abundant mineral resources, Jinchang has always attached great importance to the efficient recycling and utilization of resources. Since the development and construction of the nickel industrial base, Jinchang has given priority to the development of circular economy. After generations of continuous exploration, it has formed a "Jinchang Model" of circular economy, characterized by resource recycling, symbiotic development of industries, technological-leading, and mechanism innovation. It has been listed as one of the 12 typical cases of regional circular economy in China.

Since the production of the first batch of electrolytic nickel cathode in 1964, Jinchuan Group has continuously improved its smelting and processing level of nickel. "The hand-tearable nickel strip is a pure nickel high-precision strip, with a thickness of only 0.05 millimeters. Its good conductivity, corrosion resistance, and machinability make it stand out among many materials, and it is widely used in new energy batteries, electronic instruments, special lamps, and other structural components," said Miao Chengpeng, chairman of Jinchuan Group Nickel Alloy Co., Ltd.

From Jinchuan Group's ultra-thin nickel strip with a thickness of only 0.05 millimeters to the annual production of 5,000 tons of new energy electronic material copper foil and from the daily production of 500,000 new energy batteries to the 30,000 tons of lithium battery anode material produced by Xinjinyuan, Jinchang has accelerated the transformation and upgrading of traditional industries, as well as the cultivation and growth of emerging industries. Jinchang has developed into the largest new energy battery production base in the Hexi Corridor, and the coordinated and linked development pattern of the entire industry chain has been formed rapidly.