Cobalt is widely used in the production of high-temperature alloys, heat-resistant and corrosion-resistant alloys, hard alloys and magnetic materials. It plays an important role in the modern world, ranging from people's daily lives to the military.

In the 1960s, Jinchuan's cobalt was born. In the international environment at that time, cobalt was a scarce strategic military material. Due to the blockade of western countries and its own scarcity, "Jinchuan's cobalt" was only used for military manufacturing when it was first produced. Cobalt-based alloys or cobalt-containing alloy steel were used in blades, impellers, ducts, jet engines, rocket engines, and missiles, as well as in heavy-loaded heat-resistant components of chemical equipment, and the atomic energy industry.

In the 1980s and 1990s, the production of Jinchuan electric cobalt still adopted electrolysis after pyrometallurgy. As a new technology with high technical content, the electrodeposited production process had no previous experience in China and was in a situation of technical blockade abroad. In the face of difficulties, Jinchuan's craftsmen opened a path of innovation for technological improvement. The persistent staff of Jinchuan successfully developed new technology for the production of full-wet electrodeposited cobalt with independent intellectual property rights.

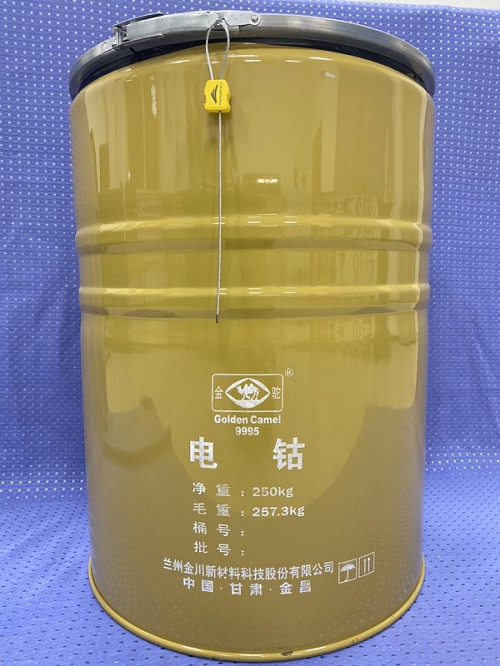

The electrodeposited cobalt of Jinchuan [Photo provided to en.jnmc.com]

In 1999, Jinchuan Group's 750t electrodeposited cobalt production line was completed and put into operation. However, due to extensive operation, high equipment failure rate, unreasonable technical parameters and other reasons, the black surface of the produced electrodeposited cobalt made it difficult to see its metal nature, and it failed to reach the most basic evaluation indicators. At that time, the quality problem of electrodeposited cobalt was a huge challenge to scientific and technological workers.

After two years of continuous exploration and the accumulation of experience, they achieved improvements in the grade of cobalt from Co9930, 9965 to 9980 by optimizing parameters and other measures.

On September 12, 2006, the successful production of the first batch of qualified electrodeposited cobalt excited the staff of Jinchuan Group.

In 2005, national cobalt production increased to about 2,000t, and it began to be widely used as an industrial raw material in the manufacturing and machinery processing industries. "Jinchuan's cobalt" also stepped onto the highway of its own development. During this period, the industry standard of "Cobalt" (YS/T255-2009) formulated by Jinchuan Group became the benchmark of cobalt product quality. At the same time, it formed its own unique brand with the excellent quality of "Golden Camel".

By 2009, the grade rate of "Golden Camel" electrodeposited cobalt product reached 100% for several consecutive years, with 60% being sold to developed countries in Europe and America.

The electrodeposited cobalt of Jinchaun Group [Photo provided to en.jnmc.com]

The electrodeposited cobalt of brand "Golden Camel" was registered on the London Metal Exchange in 2010, marking electrodeposited cobalt products entering the global market. In the same year, the "Golden Camel" trademark was recognized as a "Famous Trademark of Gansu Province" and "Famous Brand's Product of Gansu Province". It was also during this period that Jinchuan's cobalt began to expand its scope, entering the field of battery materials and new materials.

With the rapid development of the new material industry and the arrival of the electric vehicle revolution, Jinchuan's cobalt ushered in a golden era of development. Through the efforts of Jinchuan people, Jinchuan Group has become the leading manufacturer of cathode materials for electrodeposited cobalt and lithium batteries in China. At present, Jinchuan Group has formed a production capacity of 6,000 tons/year of cobalt oxide, 4,000 tons/year of electrodeposited cobalt and 42,000 tons/year of nickel cobalt manganese ternary hydroxide. The comprehensive capacity of cobalt is now 10,000 tons, specifically electrodeposited cobalt products, ranking 1st in China and 2nd in the world.

At present, Jinchuan has 3 national-level innovation platforms, 2 internationally advanced technological achievements, 7 internationally advanced technological achievements, 104 authorized patents, more than 160 proprietary technologies, 15 provincial-level scientific and technological achievement awards, and participated in the formulation of 18 national standards.